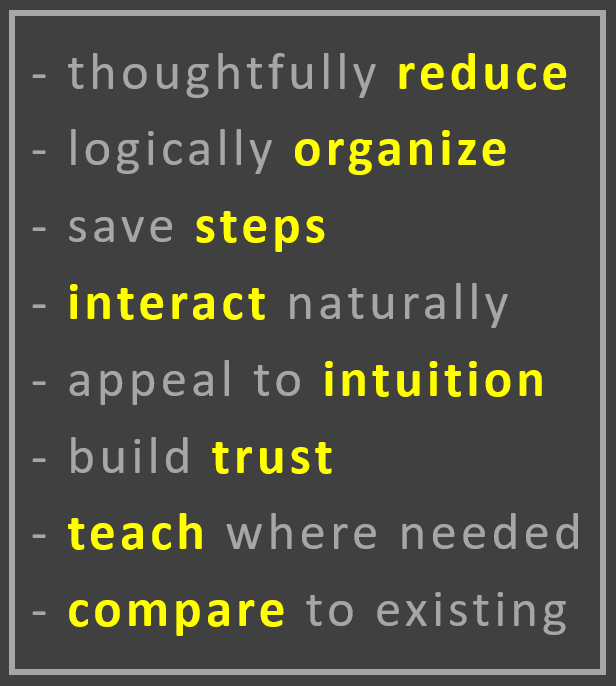

I led our crane cab redesign project, which set out to not only find a new vision for crane cabs, but also to create a recognizable brand identity across our cranes.

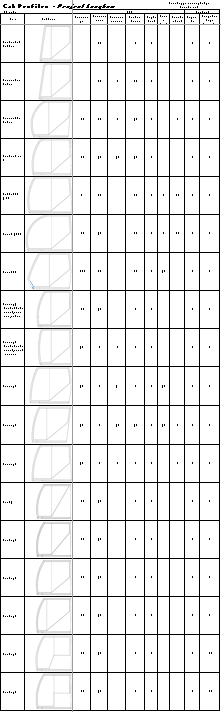

The design process began with identifying design boundaries that must be met. I broke down a generic cab shape into a series of 9 basic variables that fully defined the exterior profile and window geometry. I determined the numbers that identified current cab shapes in the market, to identify what works.

I then studied each of the base variables and expanded upon those to differentiate ourselves in the diverse crane market. I wanted to understand how the variables affected the aesthetic feel of the cab shape. We needed basic direction before beginning to build and generate 3D models, and the variables gave us that direction.

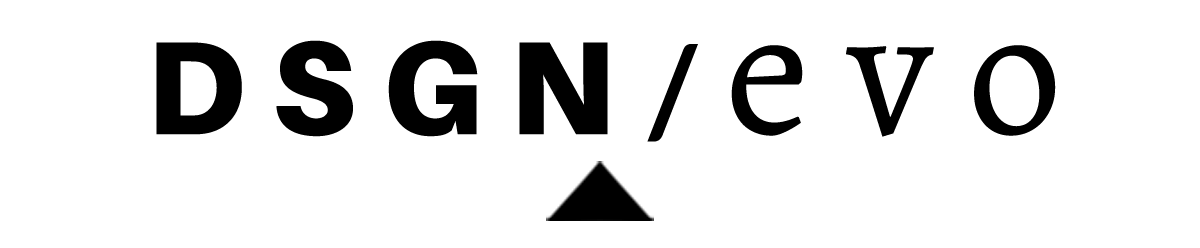

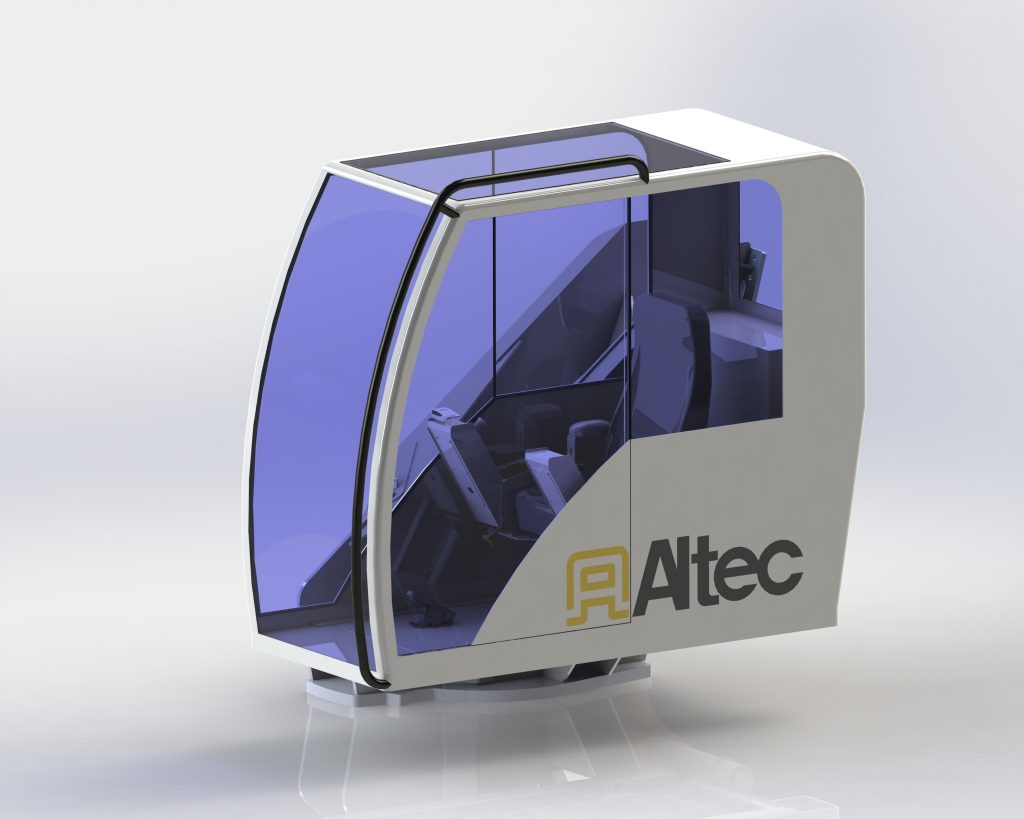

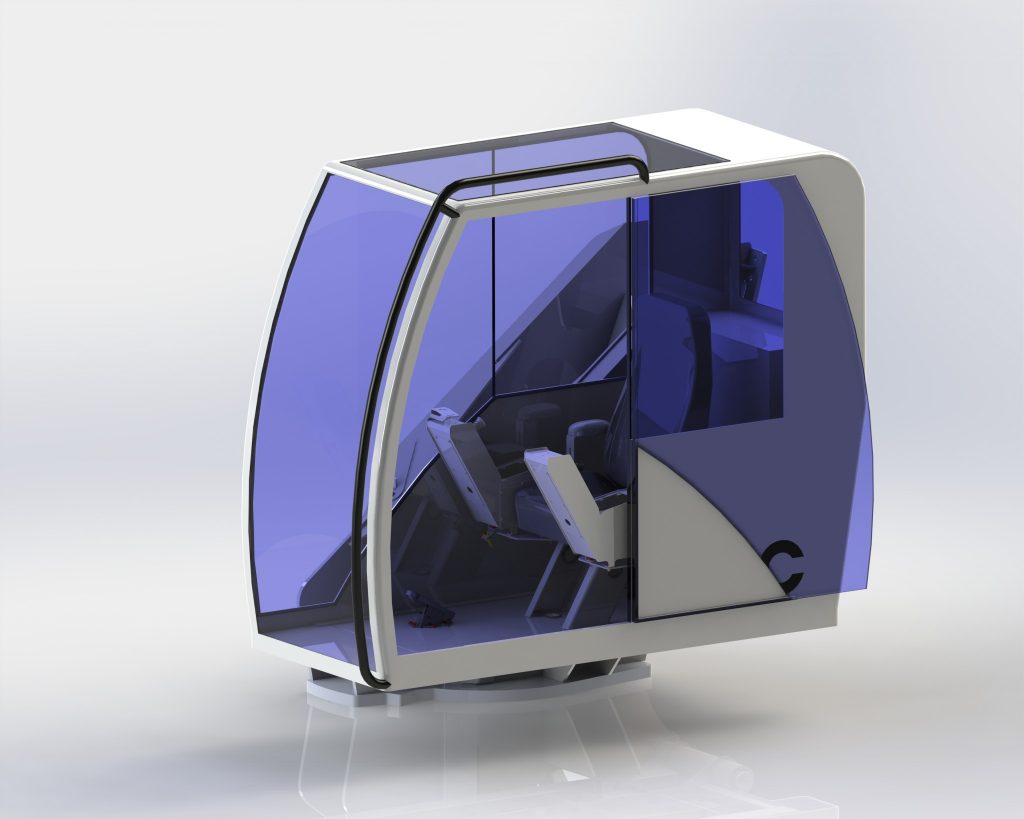

I embellished and streamlined the exterior cab look by tucking in the air conditioning system and applying a unique “branding line” across the sliding door that somewhat gives the cab a sleek motorcycle helmet appearance. I made an effort to make the cab look as good with the door open as closed, which is partly why we decided on a sliding side door vs a hinging door.

We tested many different potential cab profiles and window designs in a rendered environment to study some of the finer variables.

Safe access was a priority by providing dual access doors (patented) that provide direct access to the crane bed from most slewing positions. Safety was further enhanced by the use of shatter resistant acrylic for the front and top glass doors.

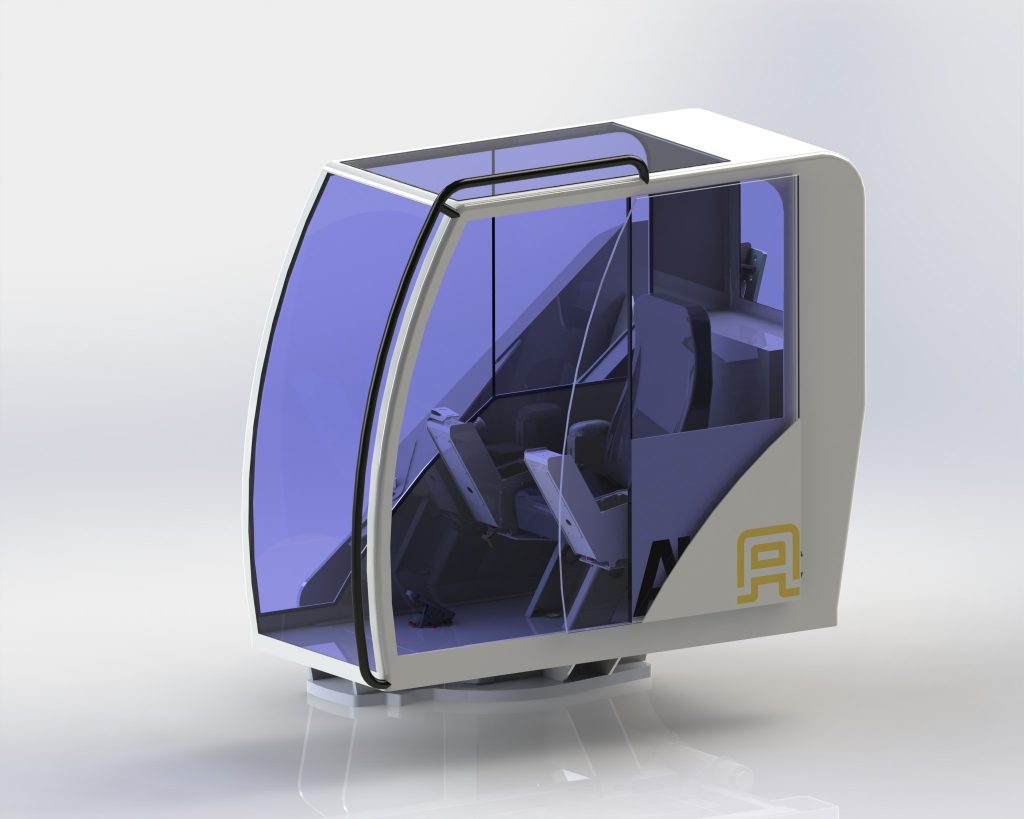

Here you can see the first prototype in early mock-up.

I oversaw the detail design and quality testing of the cab remotely through a team of designers at the manufacturing plant.